Loading...

Product Guide

Small Chamber

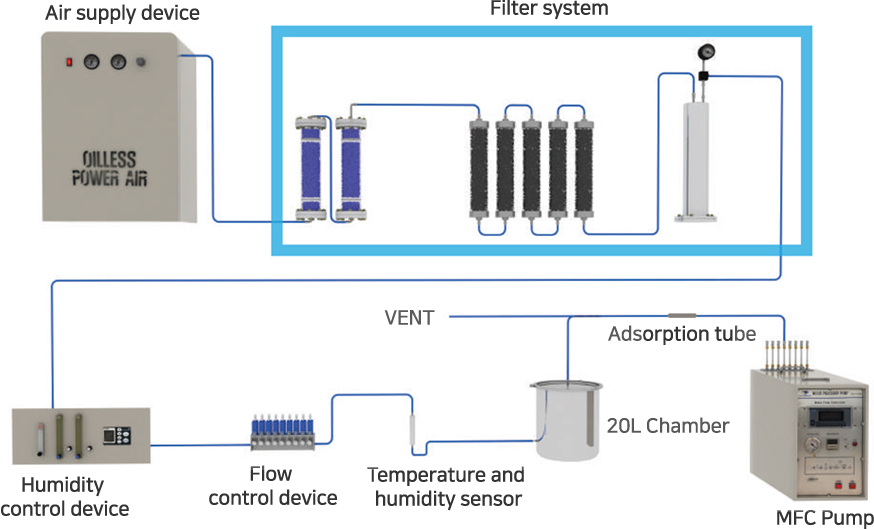

Small chamber is a device that can measure harmful substances emitted from building materials.

The small chamber system collects VOCs and formaldehyde, which are mainly emitted from building materials, by creating an environment that maintains constant temperature, humidity and ventilation.

Small chamber features

| 1 | Air generated from Air Supply Unit becomes clean air generated through three kinds of 8 step filters |

| 2 | Formed to have constant temperature, relative humidity and ventilation |

| 3 | It is possible to supply clean air into the emission test chamber and to collect quantitative samples at the exit |

| 4 | Oilless type head is used for clean air generation and 50L storage tank is used to reduce the pulse generated during air compression |

| 5 | It is possible to transmit temperature and humidity data in real time and save as files |

| 6 | It enables chamber testing of high pressure by vaporizing the tightness of the small chamber |

| 7 | Sampling Pump, which can be collect samples simultaneously in 9 chambers |

| 8 | Sample holder configuration for liquid sample (paint, adhesive, etc.) and solid sample |

| 9 | Condensation prevention by humidity control improves the accuracy of temperature and humidity due to no dew condensation inside the chamber |

| 10 | Improved humidity accuracy by mixing dry air and humid air |

| 11 | Small chamber process test method conformity with background concentration (VOCs 20μg / ㎥ or less / HCHO 5ug / ㎥ or less) |

| 12 | Small chamber holder makes transportation convenient. |

| 13 | Nine small chambers allow multiple experiments. |

Flow chart

Small chamber components

Low-temperature thermostat

It is a chamber for incubating a small chamber equipped with a sample and can accommodate up to 9 small 20L chambers. Safety devices are designed to prevent short circuit, overload and overheating.

| Capacity | 9 stage (two door chamber) |

| Display | 5.7”TFT Color LCD Touch Screen |

| Power Supply | AC220V 30A |

| Temp. range | 0~50℃ (Accuracy 0.5℃) |

| Temp. &Humidity control range | ±0.5℃ / ±0.5% (with specimens no load) |

| Allowable heat load | 1.2kw |

| Refrigerator | 600W |

| Material | SUS 304 (Electric Polishing) |

| Inner Chamber Dimension | 900(W)Ⅹ650(D)Ⅹ1400(H)mm |

| Outer Chamber Dimension | 1300(W)Ⅹ900(D)Ⅹ1820(W)mm |

Air Supply Device

Suction of outside air keeps constant pressure. The air passes through an eight-stage filter to remove moisture, organic matter from the air, and other pollutants to generate clean air with high purity.

| Clean Air TrapFilter | 3 Stage 8 Step Filter |

| Background | VOCs <20ug/㎥ HCHO<5ug/㎥ |

| Air Control | Mass Flow Controller (Max. 9-ch) |

| Mass Flow Controller | Clean Air MFC : full scale 300ml/min TotalAirMFC:2,000ml/min WetAirMFC:1,000ml/min |

| Power | 0 ~ 5VDC |

20L Small Chamber

It is a 20L chamber where samples can be put. It is packed in Teflon material and airtightness is enhanced by using an exclusive six chamber click. The supplied air flows from bottom to top and is ventilated by the amount supplied.

| type | 5 Fastener type |

| Material | SUS 304 (Electric Polishing) |

| Capacity | 20L |

Test tube fixture

It is a fixed frame that fixes the test specimen exposing only a certain surface area. To fix the specimen, pack it with Teflon material and fix it with the screw of the rear part.

| type | 4 volt fixed (2 step 8 Clip type) |

| Material | SUS 304 (Electric Polishing) |

| Capacity | W187XD187XH40mm |

Temperature and humidity sensor

It keeps temperature and humidity constant and can show temperature and humidity status in real time.

| Range | Temp. -10℃ ~ 120℃ Humidity0%~95% |

| Output 3-wire output | RH 4~20mA, Temp. passive 3-wire output |

| Accuracy ±2%, Pt 100Ω | ±2%, Pt 100Ω |

| Power | 10 ~ 35VDC |

Flow Control Device

It is a device that can constantly control the number of ventilation with constant value with the accuracy of ± 5%.

| Flow range (N2 equivalent, 20°C/1 atm) | 10 SCCM–20 SLM (freely selectable) |

| Senso | Thermal mass flow sensor |

| Valve type | Proportional solenoid valve (closed when not energized) |

| Control range | 2 –100% (F.S.) |

| Response | 2 sec. or less (0–100% within±2% typical) |

| Accuracy | ±1.0% F.S. (25°C) |

| Temperature coefficient | ±0.1 F.S./°C (15–35°C) |

| Repeatability | ±0.5%F.S. |

| Operating differential pressure | F.S. ≤ 5 SLM: 50–300 kPa (G) |

| F.S. > 100 SLM: 50–300 kPa (G) | |

| Option: Medium differential pressure (MP) and low differential pressure (LP) specifications are available. | |

| Allowable operating pressure | 500 kPa (G) or less |

| Proof pressure | 980 kPa (G) |

| Leak rate | 1 × 10-8 Pa·m3/s or less (excluding permeation of He) |

| Allowable ambient temperature | 5–45°C |

| Allowable ambient humidity | 10–90% (No condensation allowed) |

| Materials of parts in contact with gases | Body: SUS316 |

| Valve seat: FKM (option: CR or NBR) | |

| Sealing: FKM (option: CR or NBR) | |

| Electric connection | Dsub 9-pin connector as per KFC Standard (Compliant with SEMI Standard) |

| Flow rate input signals | 0 –5 VDC (Input impedance: 1 MΩ or more) |

| Flow rate output signals | 0 –5 VDC (External load resistance: 250 kΩ or more) |

| Required power supply | +15 VDC (±5%) 100 mA,−15 VDC (±5%) 250 mA |

| Joint (Main unit bore) | Standard: 1/4SWL Option: 1/8SWL 1/4VCR RC1/4, etc. |

| Weight | Approx. 1000 g |